plug flow reactor equation

Like the plug flow reactions momentum balance equation is needed to close the problem. Register for Our First Ever Rapid Cash Flow Summit Luke Lango will reveal how to start collecting cash payouts like 4600 in 48 days.

Computational Scheme For A Plug Flow Reactor Defining The Function Download Scientific Diagram

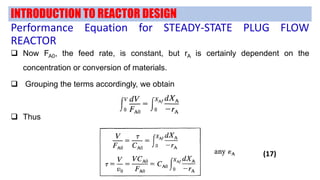

In plug flow the velocity of the fluid is assumed to be constant across any cross-section of the pipe perpendicular to the axis of the pipe.

. Each reactor will require 50 to 100 kilograms of LEU. Such an assumption does induce a degree of approximation. A single engine is comparable in size to a standard chemical RL10B-2 engine.

Working back through the computational flow to find the bugs. On applications of many types of valves. Flowserve Educational Services understands each member of your operation maintenance andor reliability crew is essential.

For example based on the PFDR approach. Batch reactors are virtually always assumed to be well-mixed. Analyses of the metering zone of a single screw extruder based on this approach have been presented for screws of constant channel depth tapered screws and for Newtonian and non-Newtonian rheological properties 11 12 1719Typical results are sketched in Figure 1114 and these indicate that higher average strains and hence mixture qualities are achieved when the.

We wish to disinfect a solution flowing at 08 m3s as it. A more accurate approach would be to model the bioreactor as equivalent to a plug flow dispersion reactor PFDR with a given value of axial dispersion coefficient 3 32 and then solve the governing performance equation numerically. DOE Category A reactor training managers determined which.

X t As t X Flow Reactor Design Equations. In later years Diesel realized his original cycle would not work and he adopted the constant pressure. Exclude carbon dioxide emissions from the combustion of biomass but include emissions of CH 4 and N 2 O from biomass combustion.

Each engine has a reactor with a thermal power of 550 MW t which heats the propellant to greater than 2600 K for a specific impulse of 890 seconds or greater exhaust velocity of 8700 ms or greater. In the 1890s a German inventor Rudolf Diesel has patented his invention of an efficient slow burning compression ignition internal combustion engine. ΔH 92 kJ mol 1 and reaches 9999 ammonia conversion at 400 C and 1 atm according to thermodynamics considering an inlet flow composed only of ammonia.

For context the qstar values are 1000000 initially and go down to 7000 or. Whether your needs include training new hires enhancing your current workforces skills or helping your crew understand new motion control technologies or products weve got you covered. Or 12000 in 21 days without touching risky.

Microbial and Chemical. A A A A F F X F time moles of A fed F X 0 0 0 inlet molar flow rate Molar flow rate at which A is. This means that a moderately high operating temperature is required to drive the ammonia.

Thus we would have N S differential equations to solve even for an isothermal reactor. Ie Q 0. We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply.

Get 247 customer support help when you place a homework help service order with us. After integration of Equation 3 using the above assumptions. Types of valves covered include gate valves globe valves ball valves plug valves diaphragm valves reducing valves.

A batch reactor is one that has no flow in or out. Biogas plant for 30 dairy cows using the Schmidt-Eggersgüss system in Germany 1952. Diesel Cycle Diesel Engine.

BTU Q 38x 105 hr Inserting the above values into the heat transfer Equation 2-2 for parallel flow heat exchanger. One other type of reactor is worth mentioning at this time. The original cycle proposed by Rudolf Diesel was a constant temperature cycle.

Reactor Batch time t required to achieve a 0 A conversion X. If temperature changes the energy balance equation must be solved simultaneously as well. In fluid mechanics plug flow is a simple model of the velocity profile of a fluid flowing in a pipe.

Tractor is carrying equipment with compressed gas cylinders. The plug flow reactor model PFR sometimes called continuous tubular reactor CTR or piston flow reactors is a model used to describe chemical reactions in continuous flowing systems of cylindrical geometry. Moles of A fed moles of A reacted For continuous-flow systems time usua lly increases with increasing reactor volume.

The plug flow model assumes there is no boundary layer adjacent to the inner wall of the pipe. Trench-type plug-flow digester with plastic fabric cover at the Cornell University Research Farm. Calculate the annual CH 4 and N 2 O emissions from the stationary fuel combustion sources in metric tons using the appropriate equation in 9833c.

It seems like the star term is quite high which results in an absurdly high dTgdT value. The decomposition reaction of ammonia is endothermic 2NH 3g N 2g 3H 2g. Vehicle at left is a slurry-transport wagon.

Design Equation Of Plug Flow Reactor Chemical Reaction Engineering Lecture 08 Hindi And Urdu Youtube

Plug Flow Reactor Vapourtec Ltd

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

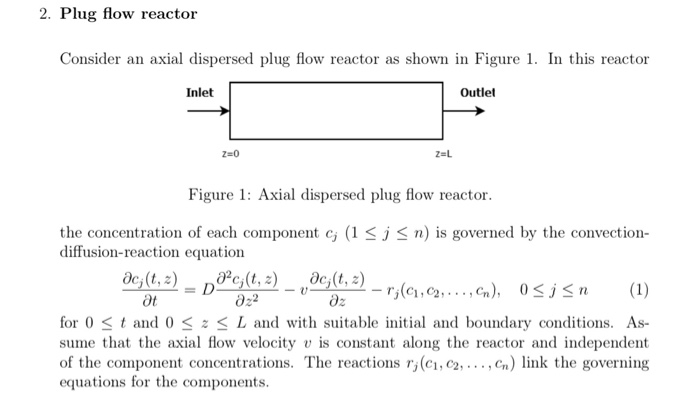

2 Plug Flow Reactor Ler An Axial Dispersed Plug Flow Chegg Com

Plug Flow Reactor Overview Youtube

Solved 4 20 Points Consider A Plug Flow Reactor As Chegg Com

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Plug Flow Reactor With Second Order Kinetics Design Equation Youtube

Mole Balance On A Plug Flow Reactor Youtube

Plug Flow Reactor With First Order Kinetics Design Equation Youtube

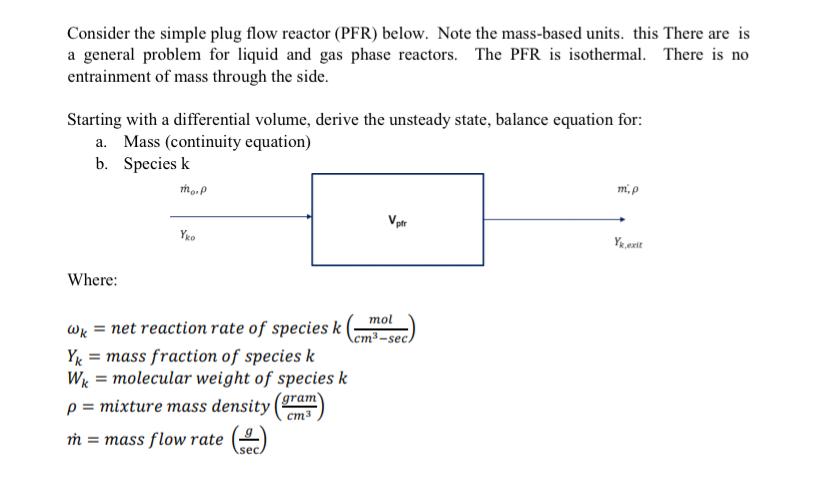

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

Matlab In Chemical Engineering At Cmu

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Introduction To Energy Balances For Plug Flow Reactors Youtube